Estás utilizando un navegador obsoleto. Puede que este u otros sitios no se muestren correctamente.

Debes actualizarlo o utilizar un navegador alternativo.

Debes actualizarlo o utilizar un navegador alternativo.

Off Topic e9 Empresas y tribulaciones en BBlau042

- Iniciador del tema dequincey

- Fecha de inicio

dequincey

Forista Legendario

- Modelo

- be em be e neun

- Registrado

- 5 Nov 2009

- Mensajes

- 11.056

- Reacciones

- 9.839

cuando trabajas con la madera, el aluminio, el vinilo, el latón cromado, los remaches, la goma,…

Da sensación de artesanía,…

y aun así hay una repetibilidad decente,

las molduras de otro, renovadas, encajan con una variación de 1 o 2mm maximo para una pieza de 90cm de longitud

la consola central con sus piezas, todas de madera, responde a un paralelismo en altura dentro de 3mm de desviacion tan solo

no se como será un alfa, un jaguar, un Mercedes coetaneos,

es curioso

Última edición:

LM Informat

Forista

- Registrado

- 16 Sep 2012

- Mensajes

- 1.277

- Reacciones

- 430

No está nada mal para entretenerse.

Mucho mejor que la Nintendo.

Mucho mejor que la Nintendo.

dequincey

Forista Legendario

- Modelo

- be em be e neun

- Registrado

- 5 Nov 2009

- Mensajes

- 11.056

- Reacciones

- 9.839

Me gusta el escudo que se aprecia en esa calandra, como se consigue uno así

Hace unos años se hizo una serie de 100 creo recordar, 00 a 99

Son la tercera serie

Los primeros se hicieron hace 25 o más años y eran cs registry usa, la siguiente serie era cs register usa

Pero para estos decidimos que tuviesen un carácter más internacional y se quitó el usa

Y son cs porque todos los e9 son cs en la placa vin

Son de porcelana vitrificada creo que hechos en usa

se agotaron pronto, yo compré la 09/100

He preguntado al que se encargó de ello por si sabe de alguna

Te diré…

Última edición:

dequincey

Forista Legendario

- Modelo

- be em be e neun

- Registrado

- 5 Nov 2009

- Mensajes

- 11.056

- Reacciones

- 9.839

hecha la cuestion, al parecer hay algun escudo de la ultima serie disponible (esquina derecha CS Register)

vamos a traer uno si o si, pero si hay mas interesados se podrian compartir costes de envio que son altos desde USA; esto beneficiaria a todos

alguno/a ?

dequincey

Forista Legendario

- Modelo

- be em be e neun

- Registrado

- 5 Nov 2009

- Mensajes

- 11.056

- Reacciones

- 9.839

dequincey

Forista Legendario

- Modelo

- be em be e neun

- Registrado

- 5 Nov 2009

- Mensajes

- 11.056

- Reacciones

- 9.839

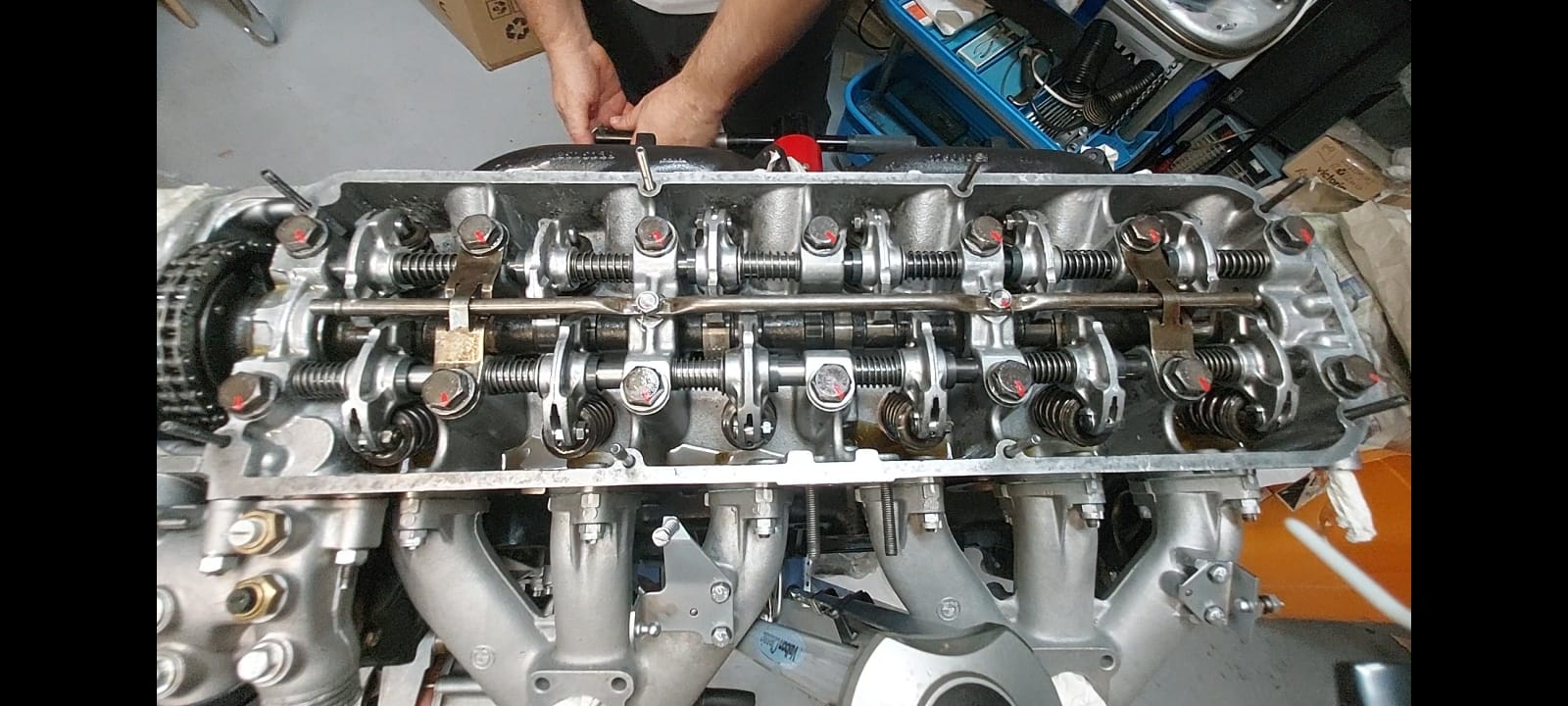

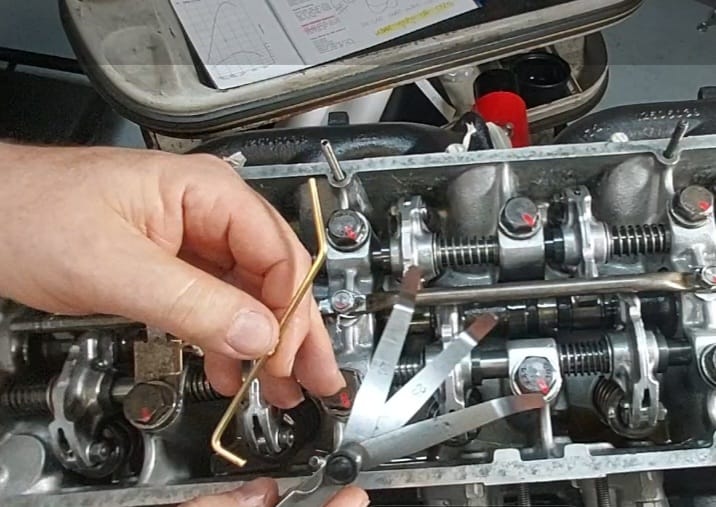

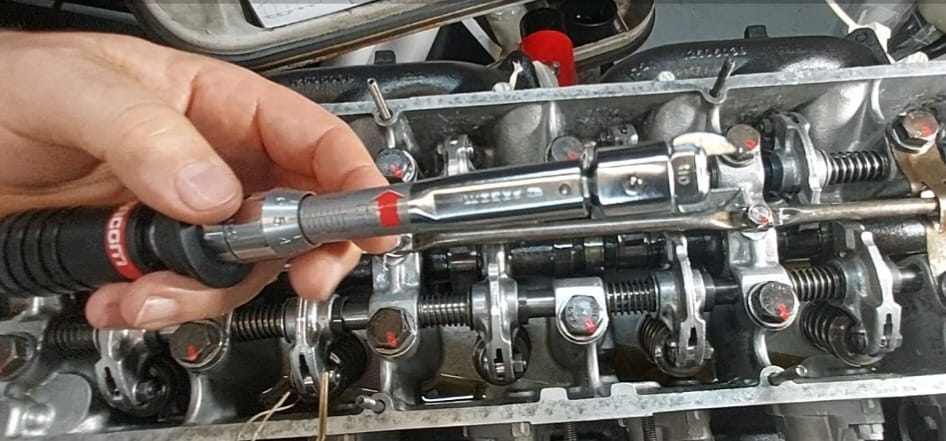

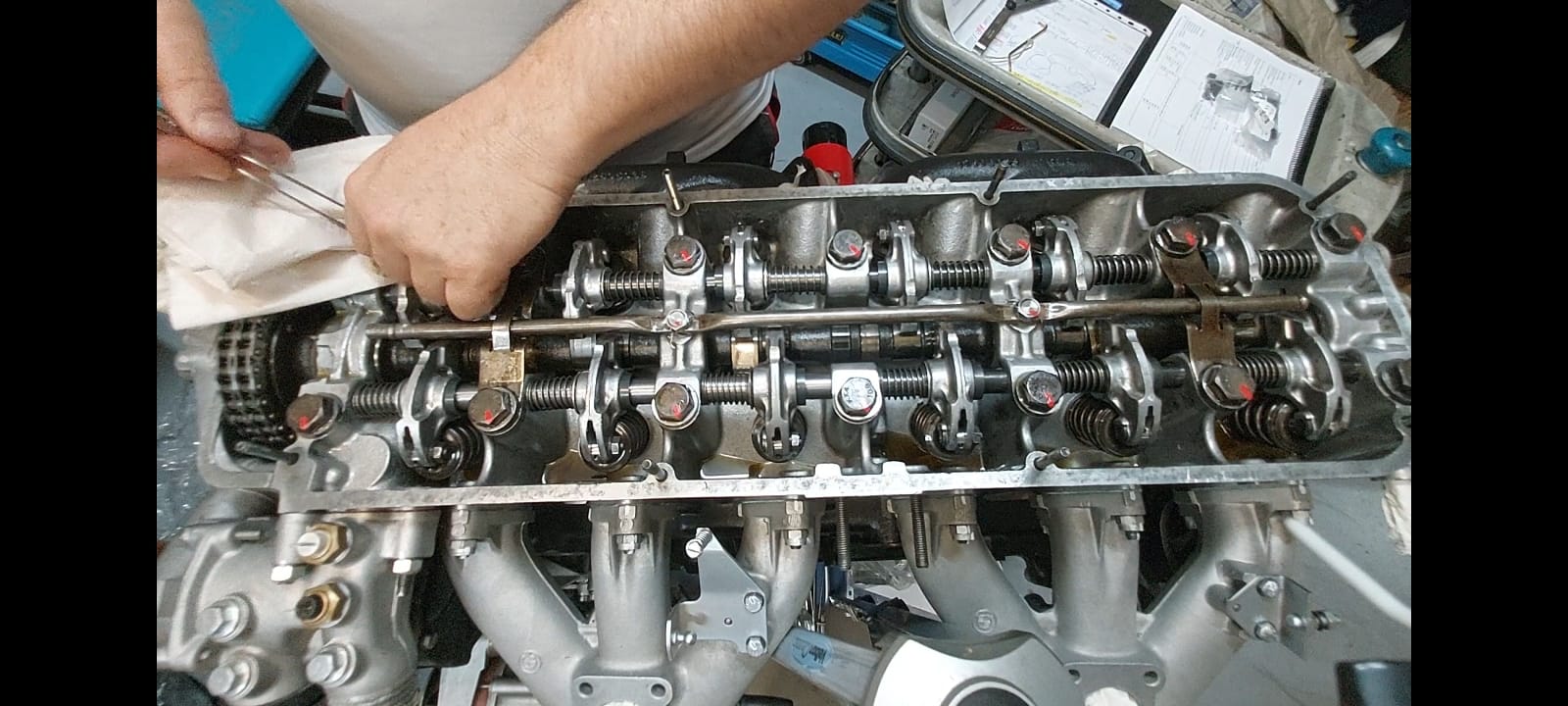

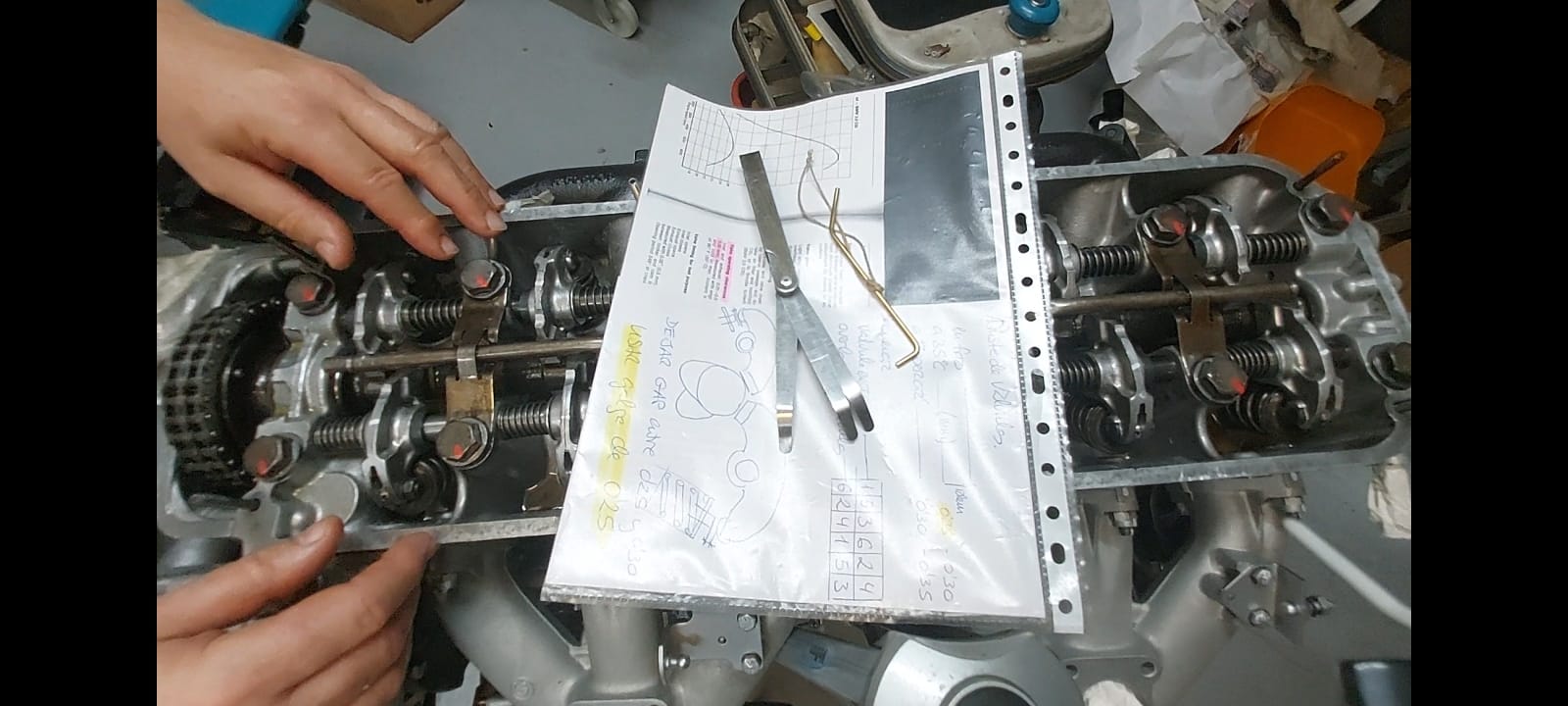

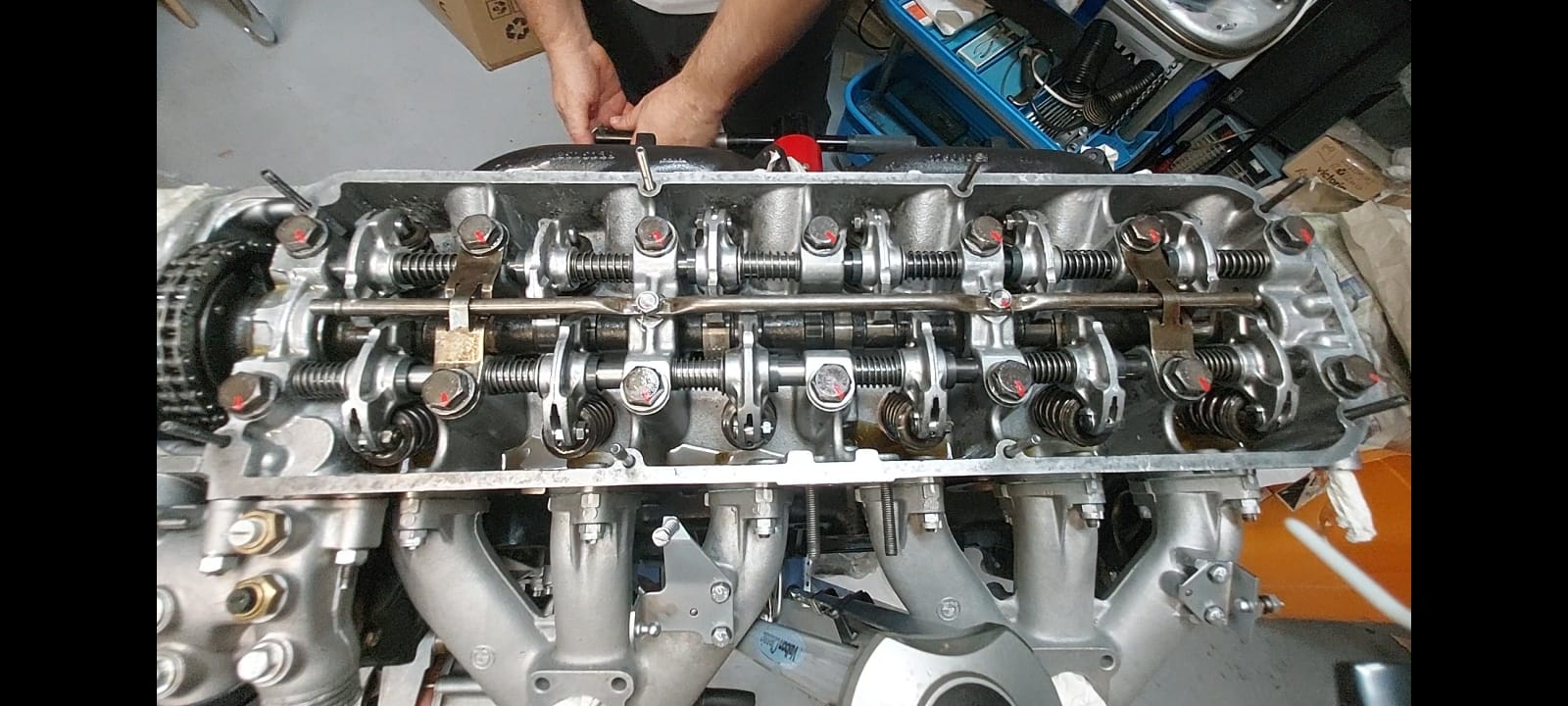

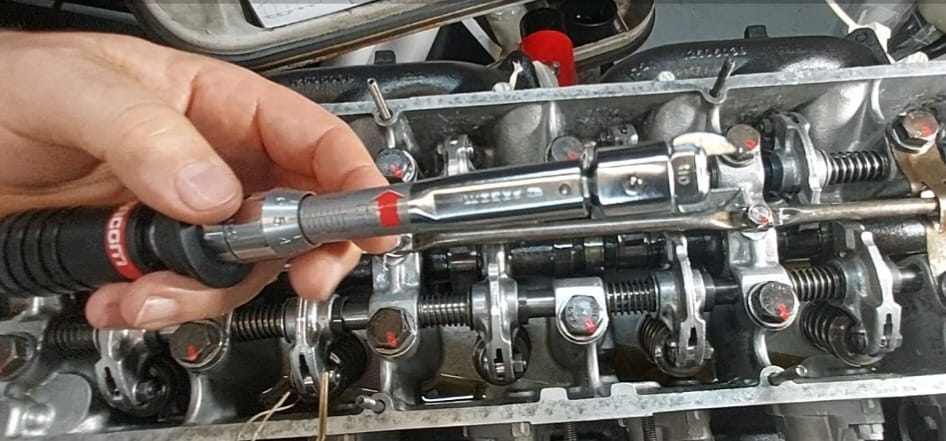

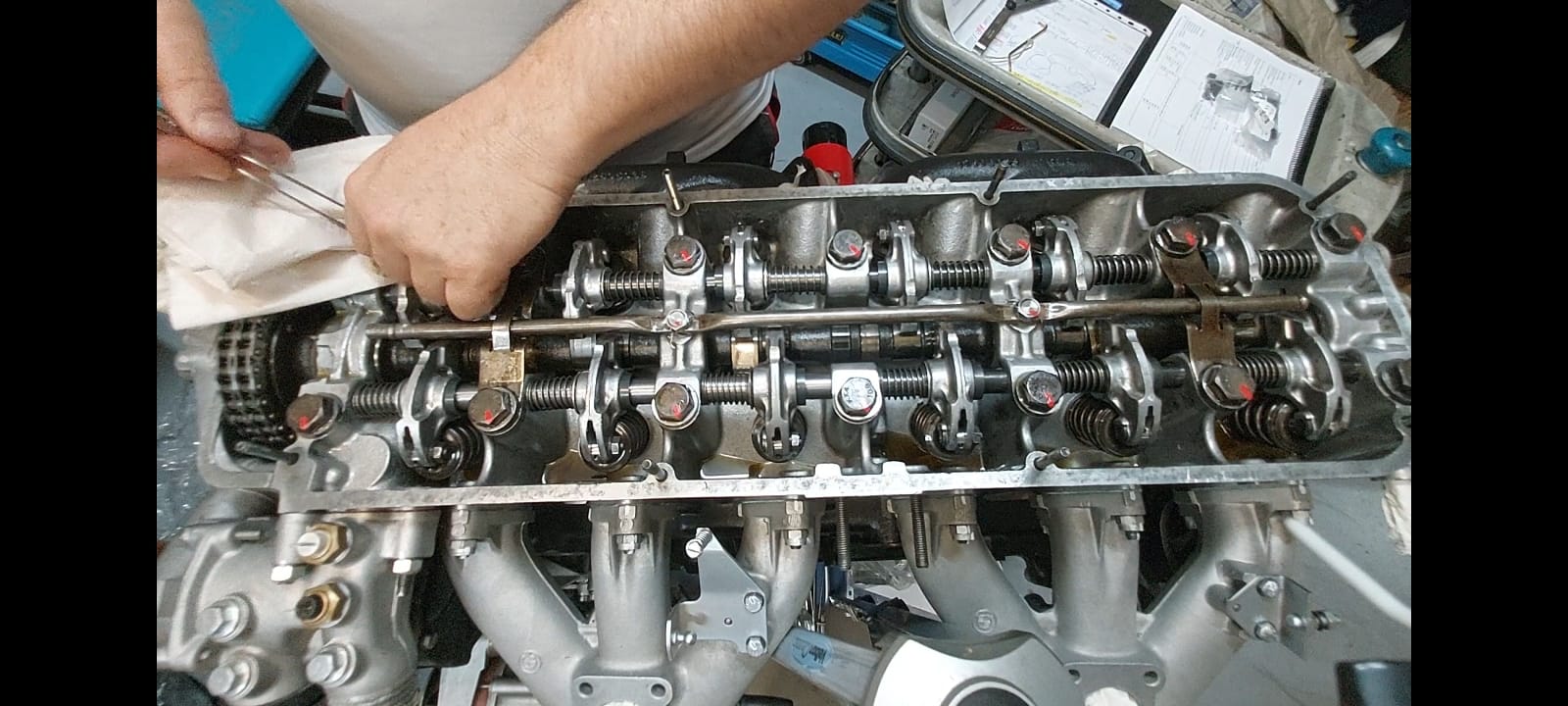

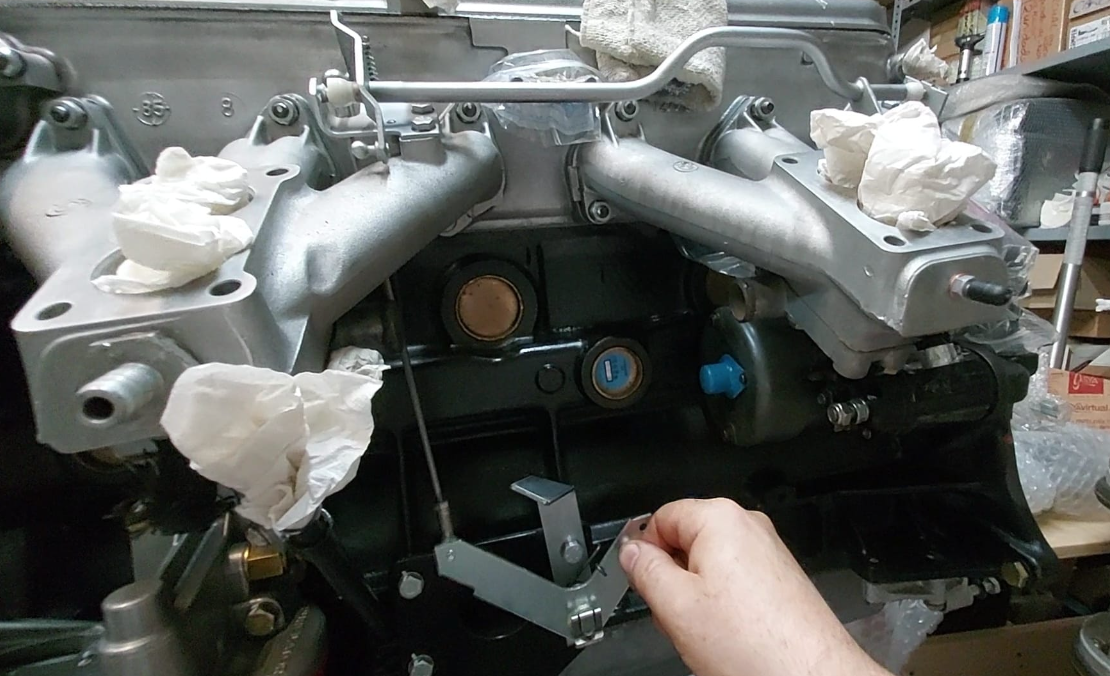

valve gap adjustment

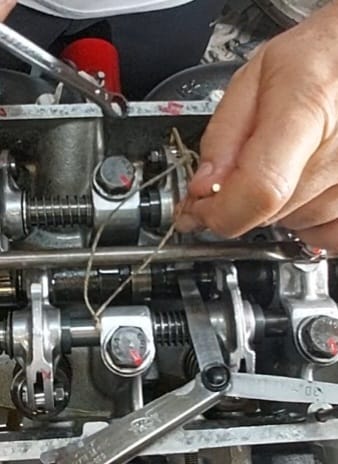

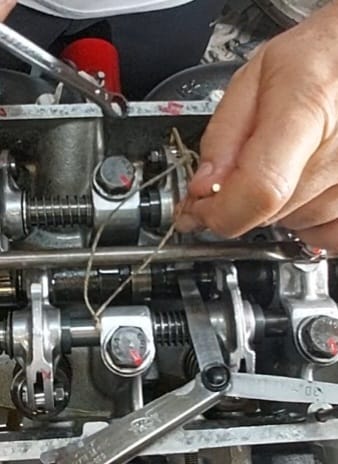

As engine is easy to access now I performed a valve gap adjustment

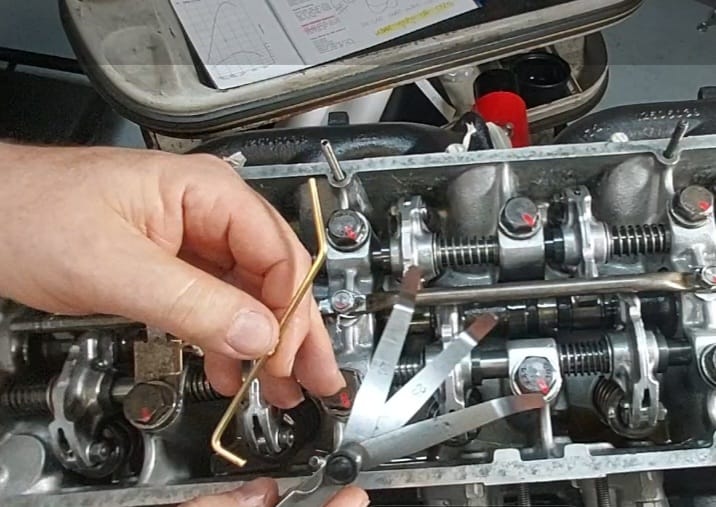

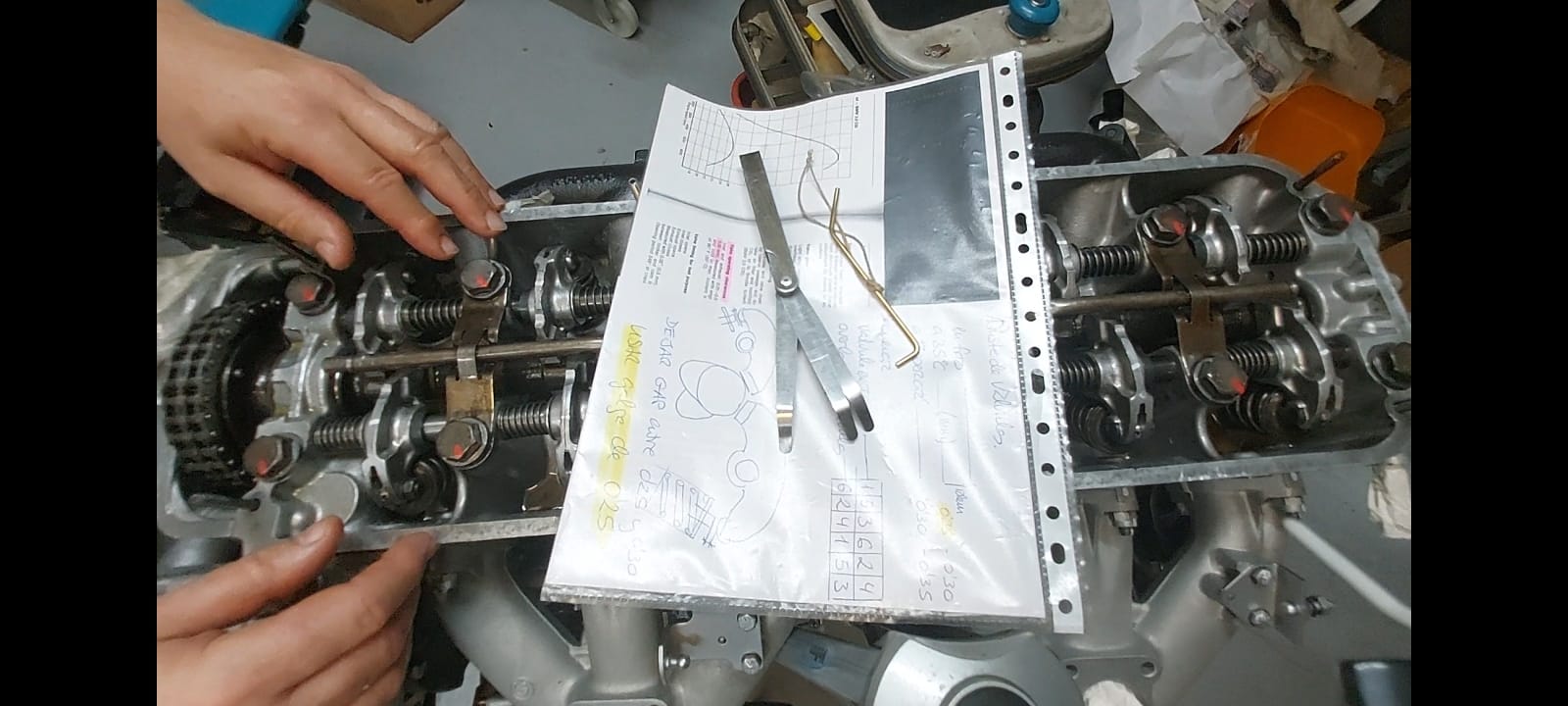

as usual , the bent tool, plus feeler gauges 0,25 and 0,30mm, a torque wrench equipped with special open end (nuts @10N.m), permanent markers, a 36 vase for the crankshaft nut, and an M10 combined wrench

first action was to replace all nuts with new ones from bmw

sequence for cylinder with closed valves in OT, from one to another remember to turn engine always clockwise when looking at engine from the front of the car

i found particularly interesting to proceed this way:

For a given cylinder choose a valve, exhaust or admission both go at 0,25 to 0,30mm gap

place the 0,25 feeler gauge between camshaft and rocker,

Using your less able hand, press the rocker with one finger to ensure gauge trapped and secure

use the bent tool to force the eccentric to contact the valve, apply pressure with a finger of same hand to secure it

With your dominant hand fix the nut, try not to change the setup, not to put pressure on the valve spring

check The gap at the valve end, if 0,25 slides well and 0,30 can’t, that one is good, so paint one mark on the rocker

once all cylinders done, I give two turns to the cranckshaft and I check it again, placing a different color mark on each rocker

i found this way much more reliable to get equivalent results at all valves

As engine is easy to access now I performed a valve gap adjustment

as usual , the bent tool, plus feeler gauges 0,25 and 0,30mm, a torque wrench equipped with special open end (nuts @10N.m), permanent markers, a 36 vase for the crankshaft nut, and an M10 combined wrench

first action was to replace all nuts with new ones from bmw

sequence for cylinder with closed valves in OT, from one to another remember to turn engine always clockwise when looking at engine from the front of the car

i found particularly interesting to proceed this way:

For a given cylinder choose a valve, exhaust or admission both go at 0,25 to 0,30mm gap

place the 0,25 feeler gauge between camshaft and rocker,

Using your less able hand, press the rocker with one finger to ensure gauge trapped and secure

use the bent tool to force the eccentric to contact the valve, apply pressure with a finger of same hand to secure it

With your dominant hand fix the nut, try not to change the setup, not to put pressure on the valve spring

check The gap at the valve end, if 0,25 slides well and 0,30 can’t, that one is good, so paint one mark on the rocker

once all cylinders done, I give two turns to the cranckshaft and I check it again, placing a different color mark on each rocker

i found this way much more reliable to get equivalent results at all valves

dequincey

Forista Legendario

- Modelo

- be em be e neun

- Registrado

- 5 Nov 2009

- Mensajes

- 11.056

- Reacciones

- 9.839

valve gap adjustment

As engine is easy to access now I performed a valve gap adjustment

as usual , the bent tool, plus feeler gauges 0,25 and 0,30mm, a torque wrench equipped with special open end (nuts @10N.m), permanent markers, a 36 vase for the crankshaft nut, and an M10 combined wrench

first action was to replace all nuts with new ones from bmw

sequence for cylinder with closed valves in OT, from one to another remember to turn engine always clockwise when looking at engine from the front of the car

i found particularly interesting to proceed this way:

For a given cylinder choose a valve, exhaust or admission both go at 0,25 to 0,30mm gap

place the 0,25 feeler gauge between camshaft and rocker,

Using your less able hand, press the rocker with one finger to ensure gauge trapped and secure

use the bent tool to force the eccentric to contact the valve, apply pressure with a finger of same hand to secure it

With your dominant hand fix the nut, try not to change the setup, not to put pressure on the valve spring

check The gap at the valve end, if 0,25 slides well and 0,30 can’t, that one is good, so paint one mark on the rocker

once all cylinders done, I give two turns to the cranckshaft and I check it again, placing a different color mark on each rocker

i found this way much more reliable to get equivalent results at all valves

aclaracion,

Al parecer la relación es x1,26. Es decir que poner 0,25 en leva equivale a 0,31 en el pie de valvula, y 0,20 equivale a 0,25

esto es teórico, por geometría, sin embargo yo no lo he experimentado, obrando como he dicho con galga de 0,25 en leva el resultado es correcto en valvula, y la galga de 0,30 no pasa

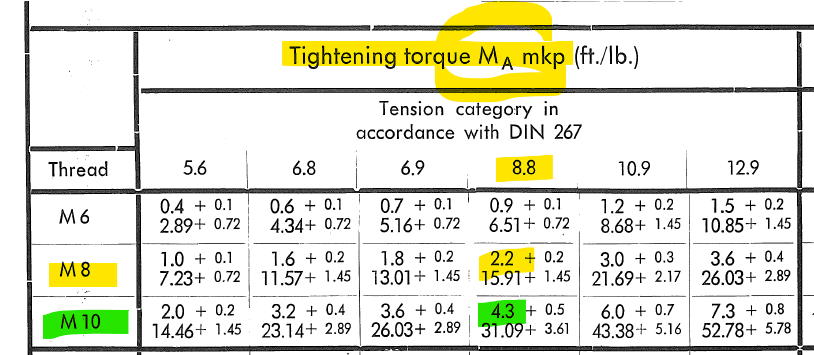

for future questions here it is a graphic aid:

">

.

Última edición:

dequincey

Forista Legendario

- Modelo

- be em be e neun

- Registrado

- 5 Nov 2009

- Mensajes

- 11.056

- Reacciones

- 9.839

un empujoncito:

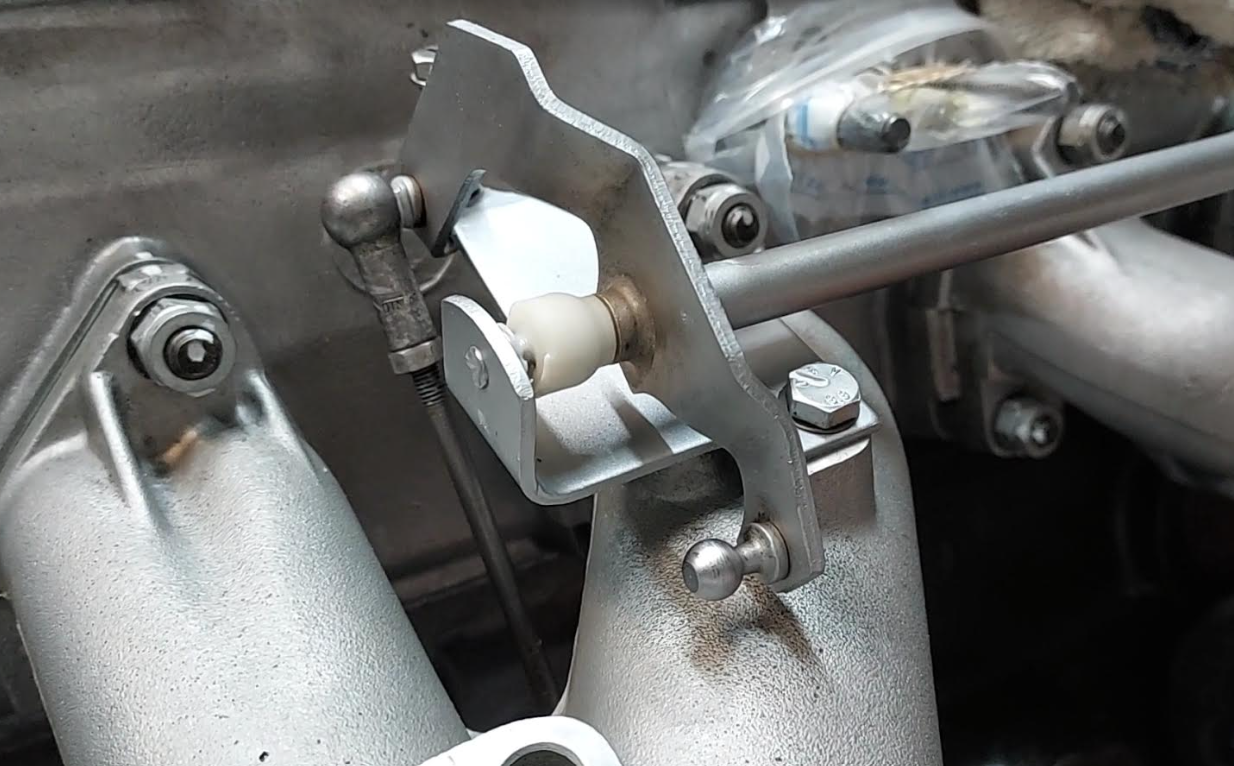

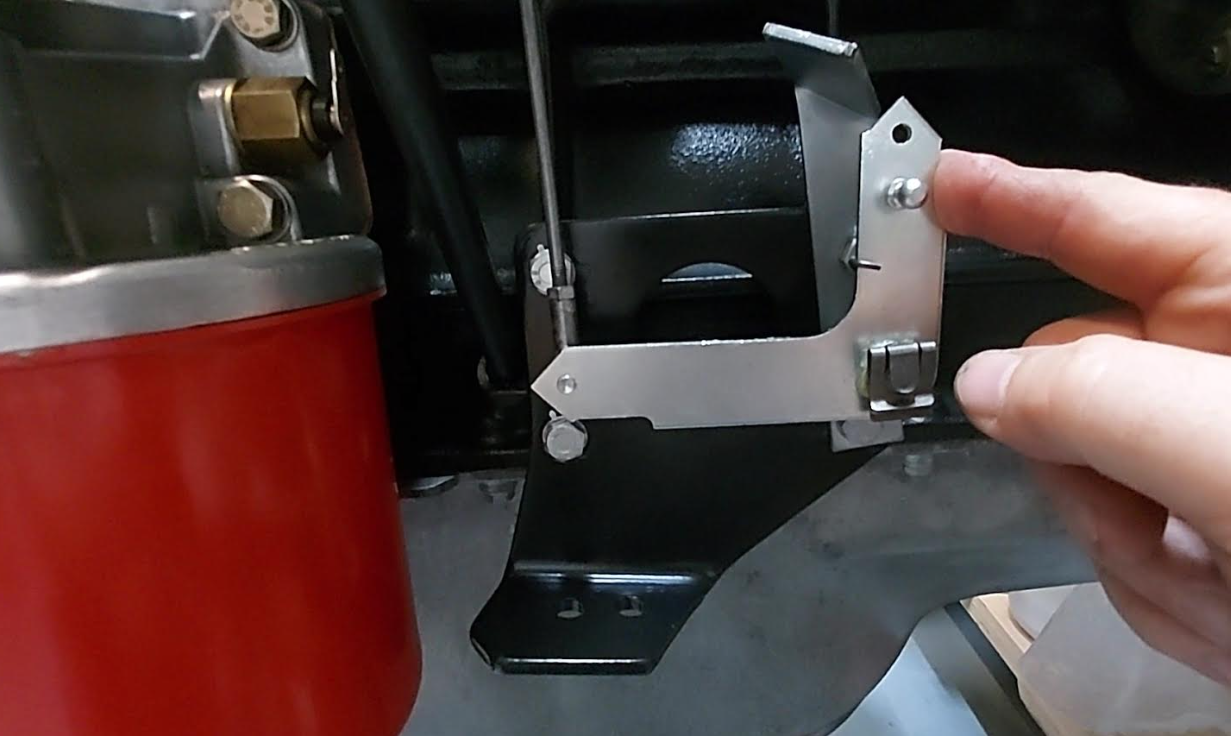

the motor mounts:

i can only set the LH due to RH being used for motor stand

for motor mounts, tightening torque values not referenced in manual, so

LH is M8 in quality 8.8 torque is 22 N.m maximum

RH is M10 in 8.8 torque max is 43 N.m

and this goes up

i know the stop plate does nothing in my setup, but it looks soo cool; i used 5mm extra length in those two bolts; i know is almost only shear force, but there was enough thread free and depth i couldnt resist (freak overkill)

creeping towards completion

the motor mounts:

i can only set the LH due to RH being used for motor stand

for motor mounts, tightening torque values not referenced in manual, so

LH is M8 in quality 8.8 torque is 22 N.m maximum

RH is M10 in 8.8 torque max is 43 N.m

and this goes up

i know the stop plate does nothing in my setup, but it looks soo cool; i used 5mm extra length in those two bolts; i know is almost only shear force, but there was enough thread free and depth i couldnt resist (freak overkill)

creeping towards completion

dequincey

Forista Legendario

- Modelo

- be em be e neun

- Registrado

- 5 Nov 2009

- Mensajes

- 11.056

- Reacciones

- 9.839

AunAún se pueden conseguir las placas anticalóricas?

- Modelo

- E24 G30

- Registrado

- 26 Dic 2003

- Mensajes

- 8.615

- Reacciones

- 2.396

Pero en la BMW?

Yo es que llevo tiempo intentando conseguir la del M635 E24 de protección de los colectores y nanay desde hace años.

dequincey

Forista Legendario

- Modelo

- be em be e neun

- Registrado

- 5 Nov 2009

- Mensajes

- 11.056

- Reacciones

- 9.839

Pero en la BMW?

Yo es que llevo tiempo intentando conseguir la del M635 E24 de protección de los colectores y nanay desde hace años.

si, compre el año pasado en bmw

- Modelo

- BMW Nipón

- Registrado

- 5 Oct 2018

- Mensajes

- 5.602

- Reacciones

- 20.805

dequincey

Forista Legendario

- Modelo

- be em be e neun

- Registrado

- 5 Nov 2009

- Mensajes

- 11.056

- Reacciones

- 9.839

the bumpers job...continuation

">

using 4mm SS rivets

mark the position of the holes, and make the first one, start center and move towards ends

">

mark, punch, and drill

adapt the shape

and fix with rivets

">

using 4mm SS rivets

mark the position of the holes, and make the first one, start center and move towards ends

">

mark, punch, and drill

adapt the shape

and fix with rivets

Similar threads

- Respuestas

- 5

- Visitas

- 730

- Respuestas

- 4

- Visitas

- 971

- Respuestas

- 3

- Visitas

- 249

- Respuestas

- 5

- Visitas

- 535